Beer, malt and wort analysis

Malt, Wort and Beer analyses are essential to control brewing quality during beer production. Skalar offers full automation for several parameters in the analysis of beer.

QUALITY ASSURED

The beer, malt & wort analyzers have completely integrated methods according to EBC, ASBC and MEBAK and have been successfully installed at many beer and malt laboratories worldwide. The automated analysis achieves better response times, less operator intervention and an increased accuracy in the results

ACCURATE RESULTS

The ability of Skalar’s instrumentation to give accurate results time after time is what most people regard as the deciding factor before purchasing a system. Over a period of years, our application laboratory has worked with brewing and malting laboratories to achieve rapid, accurate and reliable results

TIME EFFICIENT

An important factor for efficient laboratories is time. Automation of the analyses with the SAN++® Series, PRIMACS™ Series and SP2000 Series reduces the analysis times and increases the sample throughput. The response times to the detection of changes in production are more immediate which ensures a better control of the production process and waste reduction

COST EFFECTIVE

The analyzers have proven to be robust workhorses for the brewing and malting laboratories. The low operational costs simplify the choice to automate applications, bearing in mind an increase in speed and reliability. In addition, less waste per sample analysis is produced compared to the traditional manual method

Our automated solutions for the brewing industry

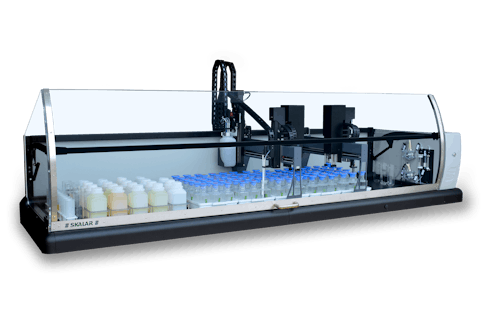

The SP2000 Series analyzer has been specifically developed for breweries that only need analyses on small batches of samples on single or multiple parameters. Every couple of hours, beer and wort samples need to be tested on various parameters and the results need to be provided instantly to the operators who control the brewing process. Besides this, breweries nowadays produce smaller batches of different beers instead of only large quantities of one beer.

Features

- Complete automation incl. degassing of the samples, (de)-capping the sample tube, sample dilution, addition of reagents, mixing and measurement of the absorbance

- Flexibility to process small or large batches and run single or multiparameter analysis

- The iso-octane reagent consumption is reduced by a factor of 5 compared to the manual method

Parameters

- Color

- SO2

- Iron

- Bitterness

- Thiobarbituric Acid Value (TBZ)

- pH

- Polyphenol

- Free Amino Nitrogen (FAN)

- Anthocyanogen

- Beta (β) glucan

The SAN++® Series is ideal for analyzing large series of beer & malt samples in one batch on multiple parameters with complex analysis methods such as diacetyl, polyphenols and anthocyanogen. A typical five channel beer analyzer is configured with modules for bitterness, total SO2, free amino nitrogen, polyphenols and diacetyl. A malt analyzer usually carries applications such as diastatic power, α-amylase, FAN, ß-glucan and color.

Features

- Methods according to EBC, ASBC, MEBAK etc.

- Unattended automatic start-up and shutdown

- Integration of various detectors for beer & malt analysis, such as the fluorimeter and the UV/VIS detector

- FlowAccess software with real time graphics, data calculation and data export to Excel/LIMS

- Analyses of up to 16 parameters at the same time

- Autosamplers range from 50 up to 576 sample positions

Parameters

- Acetaldehyde

- Amino Nitrogen (free)

- Amylase

- Bicarbonate

- Bitterness

- Carbohydrate

- Carbonate

- Color

- Density

- Diacetyl

- Diastatic Power

- Ethanol

- Glucan

- Nitrate + Nitrite

- Nitrogen

- pH

- Polyphenols

- Protein

- Protein Soluble

- Sulfite

- Sulfur Dioxide

- Viscosity

The routine monitoring of total nitrogen / protein content during the brewing process is important to ensure the quality and stability of the beer products. Protein present in malt and wort is an important nutrient for yeast to ferment wort into beer. By measuring nitrogen, brewers can indicate the protein content in malt and wort.

Features

- Alternative for Kjeldahl analysis

- Sample weights up to 3g of solids

- 100-position autosampler

- Unique vertical sample introduction system

Range of analyzers for the Brewing Industry

Malt, Wort and Beer analyses are essential to control brewing quality during beer production. Skalar offers full automation for several parameters in the analysis of beer.